Improving student learning with physical teaching tools

The Faculty of Engineering has developed novel physical tools for teaching the properties of structural steel, to help students understand the behaviour of steel beams used in construction and how complex engineering concepts relate to real-world applications. These are especially applicable to the year 3 courses: Structural Engineering STRCTENG 302 and 304 and year 4 courses: STRCTENG 710 and 711.

Background

Research has identified a knowledge gap amongst structural engineers and students when linking mathematical theory to the physical behaviour of steel members under load; specifically two critical concepts – the lateral torsional buckling (LTB) and the local buckling (LB) of steel beams when being bent or loaded in compression. Data showed that > 20% of students and many practising engineers struggled to understand links between the sometimes complex mathematics and physical behaviour. It is well known that including physical models in teaching can improve student visualisation and active learning of structural behaviours. However, with the exception of impractical/unfeasible full-scale test rigs, teachers have had to rely mostly on theoretical explanations, static images and unrealistic cardboard models to demonstrate these difficult concepts. Students who struggle to understand these have often delivered poor results and expressed frustration at outdated models that do not effectively bridge the gap between theory, physical behaviour, and standard industry codes. This prompted the academics involved and Kris to develop an effective physical teaching tool that has already helped to improve student grades and feedback, and shows great promise for future applications.

The project

Having realised the difficulty with teaching this specific area of structural engineering, Kris aimed to create a teaching apparatus to help visualise the concepts of LTB and LB. Polyurethane rubber was selected for its physical properties, enabling the globally recognised primary technical steel design code (NZS3404) to be applied directly to teaching demonstrations, alongside accurate theoretical mathematics and clear visualisation of the difficult concepts. Essentially, it tied together all aspects required for students to grasp the concept while incorporating steel design codes (a world first).

Three tools were produced – two were handheld items that students manually ‘induce’ LTB and LB, to experience the effects of bending and shearing forces, and the main tool was a polyurethane I-beam. Seven replicas were introduced into structural engineering (STRCTENG 302) labs in 2022, so that small groups of students had access to their own rubber beam. The group environment increased student engagement, discussion and learning, and the labs coincided with a graded assignment to fully utilise the features and functions of the tool. Students completed a range of setups, then used steel design code NZS3404 and theoretical mathematics to calculate beam load; thus incorporating all aspects of authentic steel beam engineering design.

The rubber beams – which can demonstrate a wider range of behavioural modes without the explicit link to the mathematics – have also proved a very good visualisation tool for year 4 courses: STRCTENG 710 and 711.

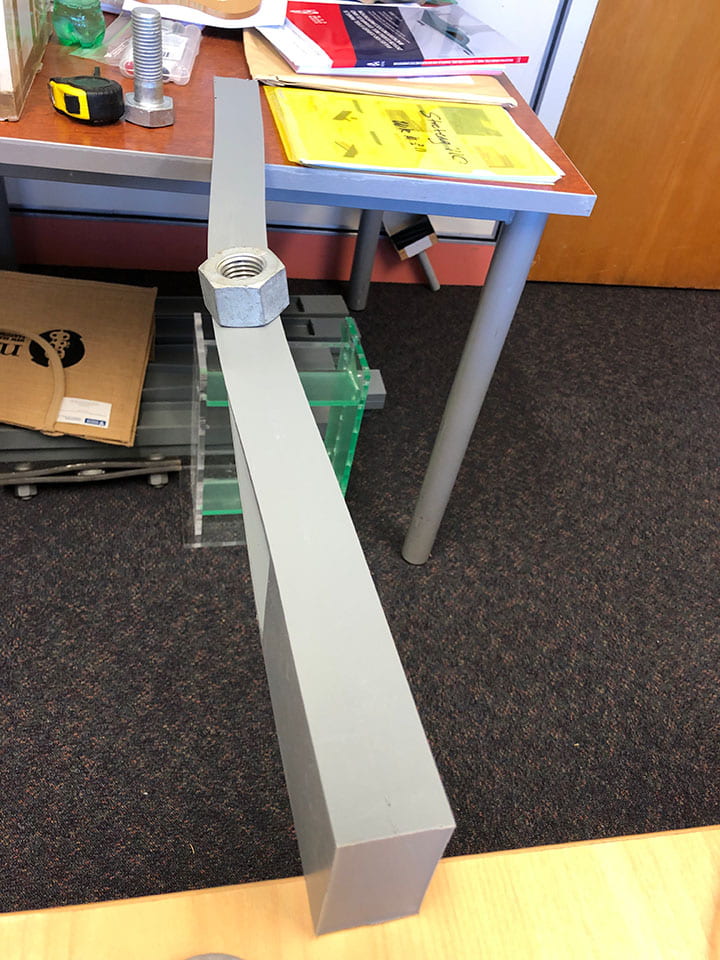

Kris Cheng demonstrates how adding stiffeners to the rubber beam can help reduce lateral torsional buckling.

Three tools were produced – two were handheld items that students manually ‘induce’ LTB and LB, to experience the effects of bending and shearing forces, and the main tool was a polyurethane I-beam. Seven replicas were introduced into structural engineering (STRCTENG 302) labs in 2022, so that small groups of students had access to their own rubber beam. The group environment increased student engagement, discussion and learning, and the labs coincided with a graded assignment to fully utilise the features and functions of the tool. Students completed a range of setups, then used steel design code NZS3404 and theoretical mathematics to calculate beam load; thus incorporating all aspects of authentic steel beam engineering design.

The rubber beams – which can demonstrate a wider range of behavioural modes without the explicit link to the mathematics – have also proved a very good visualisation tool for year 4 courses: STRCTENG 710 and 711.

Outcomes

In previous structural engineering education, students were expected to apply steel design code to assignments largely comprised of static images and dense theory. The novel teaching tool and related activities allowed students to visualise the concepts they were learning, as well as discuss and explore these in a laboratory group. In addition to the active learning elements, students were also responsible for collecting their own results to be used in their assignment, and they could use their physical lab results to back-calculate equations if they became stuck.

Academic performance and student feedback were the primary metrics used to determine if student learning improved. Due to several factors it was not possible to make a direct comparison to past student performance; however, the results suggested that the implementation of the tool helped improve academic performance regarding structural steel design. Student feedback was positive –more than 80% of the responses showed that the learning environment increased student engagement and collaboration, and students reported they were receiving quality teaching. Their exposure to the tools was the key factor in creating the interactive learning experience, which was also well received.

Future implications

Given the success of the teaching tools in this research, a long-term goal is for universities worldwide to adopt them into their curricula. The application of steel structural code NZS3404 to polyurethane beams (that mimic steel beams) also presents significant new opportunities, not only for teachers and students, but also for the steel construction industry. Polyurethane is a naturally occurring polymer and the application of the material can potentially be applied at large scale. On-going research will determine whether stiffer grades of polyurethane could be used for more cost-effective and environmentally friendly beam and connection designs. Furthermore, a Part 4 Research Project in 2023 is developing physical models to show the behaviour of rigid bolted connections involving steel plates loaded ‘out of plane’, which is also a difficult concept to understand.